Take your production to the next level.

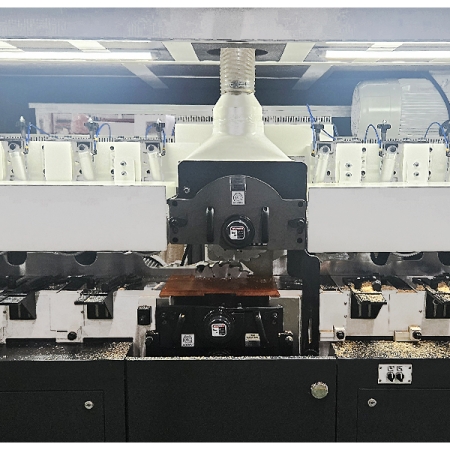

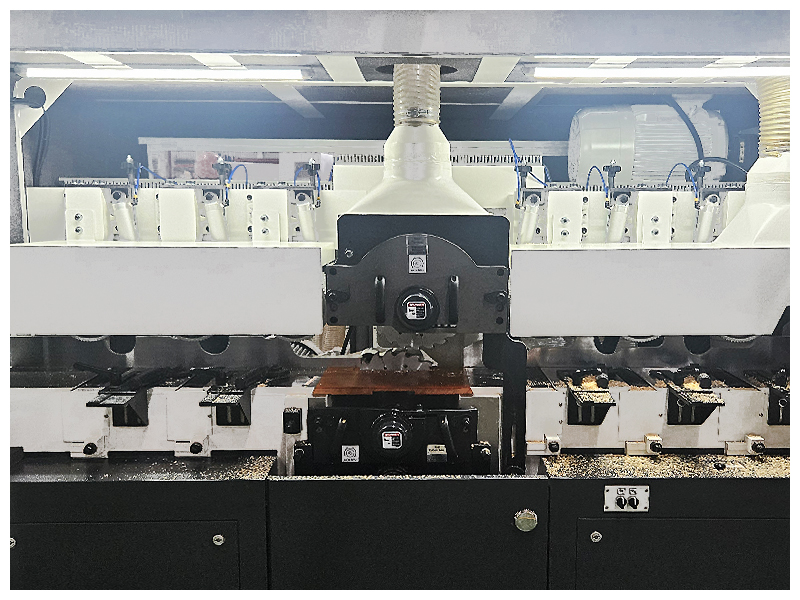

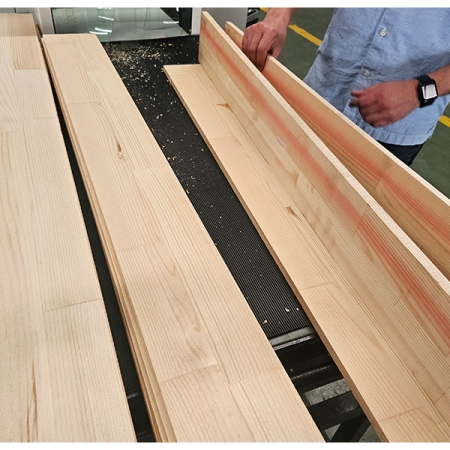

Take your production capabilities to the next level with the Leadermac 255MM Top & Bottom Multiple Ripsaw—meticulously designed to meet the demands of today’s manufacturing environments. Built for high-performance settings, this machine delivers unparalleled efficiency, precision, and yield.

Whether you’re optimizing throughput or fine-tuning for accuracy, the LMC 255MM offers the power and reliability you need to stay ahead. With advanced engineering and a rugged build, it’s the smart investment for operations that demand more.

Why Leadermac 225MM Top & Bottom Multiple Ripsaw?

- Full sound and safety enclosure provides a quieter, safer working environment by covering the entire machine

- Feeding table surface is chrome-plated and hardened to 0.3 mm for enhanced durability and extended service life

- Single-stage pneumatic feed roller pressure system adjusts for significant variations in workpiece thickness, with a maximum pressure setting of 6 bar

- 1-meter infeed table with edge jointing fence offering a 10 mm adjustment range

- Equipped with 6 top steel feed rollers and 5 bottom steel drive rollers for consistent material handling

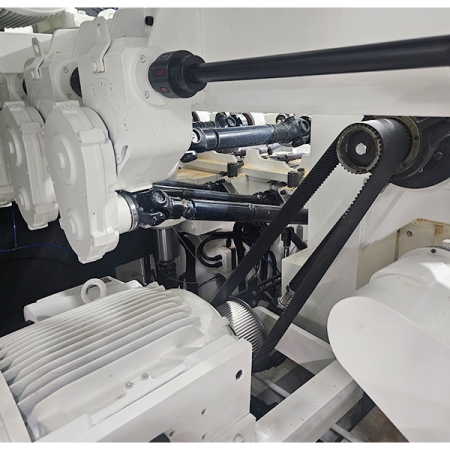

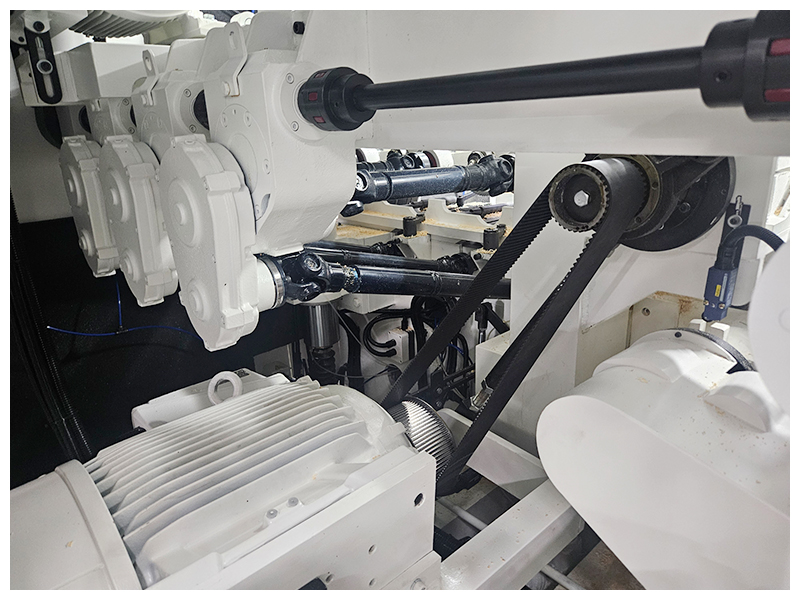

- All horizontal spindles are supported by hydraulic outboard bearings for increased stability and performance

- Spring side pressure roller for the infeed table

- Bottom steel feed rolls can be raised and lowered using a wrench

- Additional top anti-kickback device for splitting operations

- New, more robust design of the anti-kickback device for enhanced safety

- Increased finger thickness from 6mm to 9mm

- Spacers added to all fingers

- Finger angles adjusted from 21° to 35°.

- Finger material upgraded from SS41 to S45C

- Bar (shaft) diameter increased from 19mm to 25mm

- Shortened bottom fingers to prevent catching beneath the table

- Extra safety switch on the rear door to prevent saw blades from colliding with feed rollers

- Enhanced dual bottom dust hood for improved extraction efficiency

- Outboard support bracket for 225 mm components.

- Bottom cover features an extra filter tray and a 6” ventilation port

- Upgraded drive system using a cogged belt with motor and spindle pulleys, replacing the standard belt for improved durability

- Timing belt and timing pulley

- Arbor drive features a driven shaft with an increased diameter at the end and extended shaft length

- Outfeed guard specifically for the LMC225MM model

- Individual dust extraction hoses, clamps, and flanges for each spindle

- Amper meter for monitoring electrical load

- Electrical cabinet equipped with extended 3-meter cables for flexible installation

- Mobile control unit with a 7-meter cable for ease of operation

- Remote hand pendant control for feed roller direction (forward/reverse), replacing the standard fixed control

- Safety limit switch on the rear door – Machine halts when either of the two doors is opened

- Air pressure regulating for precise control

- Zero-speed sensing system with integrated safety module

- 75 HP spindle motor equipped with an inverter brake (280V~500V)

- Integrated 10” cooling fan for thermal management