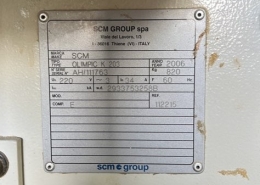

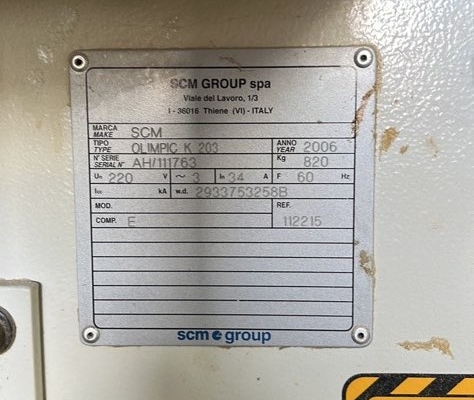

SCM

Used Olimpic K203 Edgebander

Machine Information

- Automatic adjustment of all the units when the panel thickness is changed

- Excellent gluing using hot-melt glue

- Automatic loading for coiled edges and strips

- Accurate and precise machining with 12,000 rpm motors

- strip edging thickness: 5 mm

For hot melt glue in granules. Glue pot beneath the operating line. The glue is applied to the panel with a roller

End trimming unit

- With two independent motors sliding on prism guides. Can be tilted from 0 – 15 degrees, manually

- Moves on ground guides with re-circulating ball screw brushes. (Front and side copiers and digital mechanical indicators.

ROUND K rounding unit

- Compact, easy to use and precise, with two motors which slide on prism guides. It ensures the perfect finishing of thin or 3 mm PVC/ABS edges in a single pass. It can also be used as an edge trimmer and has a 2-position KIT for switching from a thin edge to a 3 mm edge without the need for any adjustments

Scraper unit

- Compact and particularly solid for perfect finishing of 3 mm PVC/ABS edging

Brushing unit

- For perfect cleaning and polishing of the edges, with a timed nebulizer

Edge loading and pressure standard equipment

- Automatic loading for coiled edging and strips

- Cutter for coiled edges. Max. thickness 3 x 45 mm

- 3 edge pressure rollers, the first roller is power-driven with build in clutch