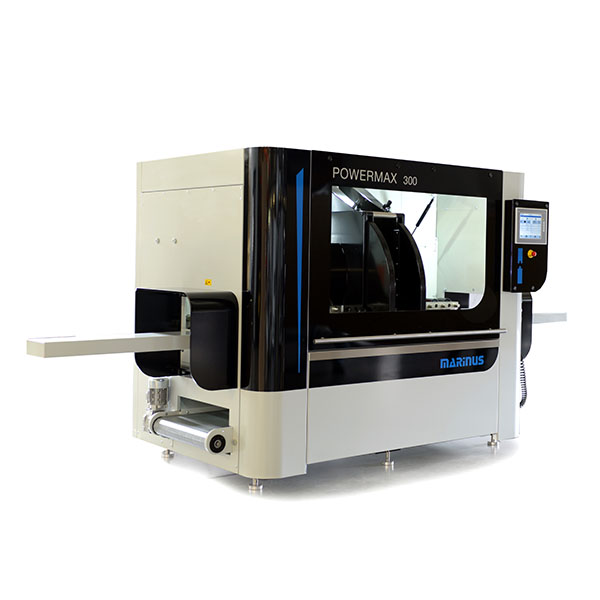

The ONE machine that cuts out defects, cuts to length, and endmatches.

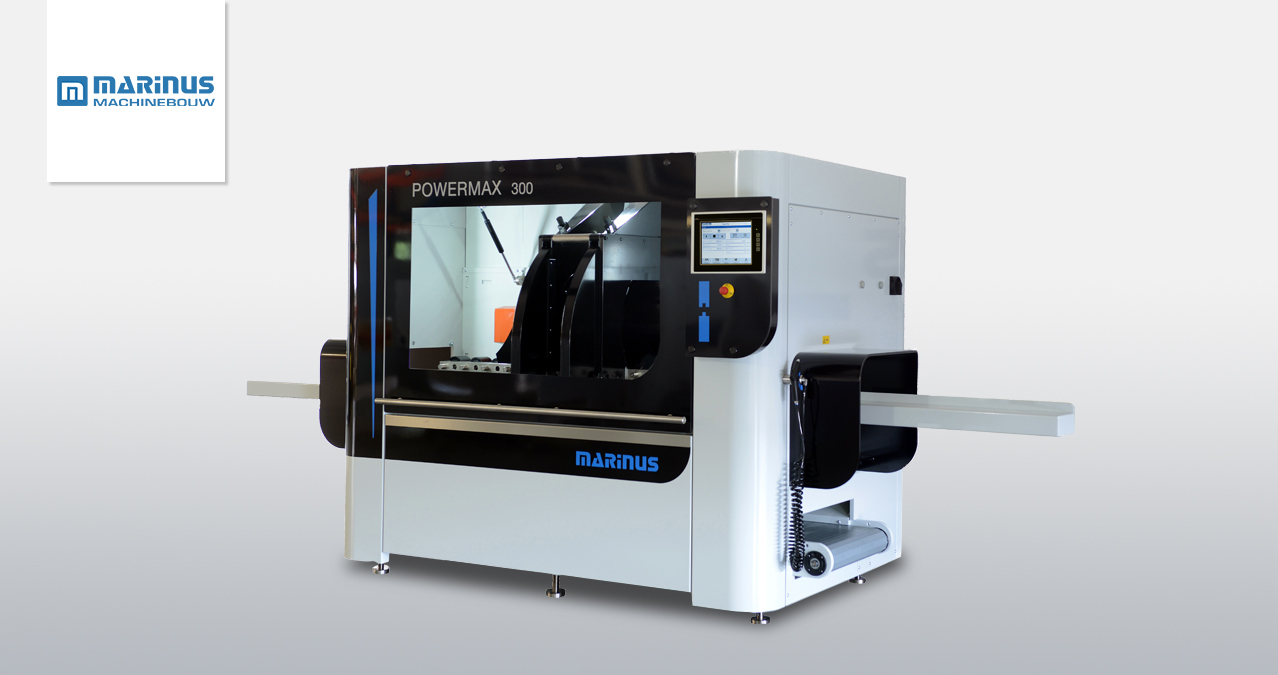

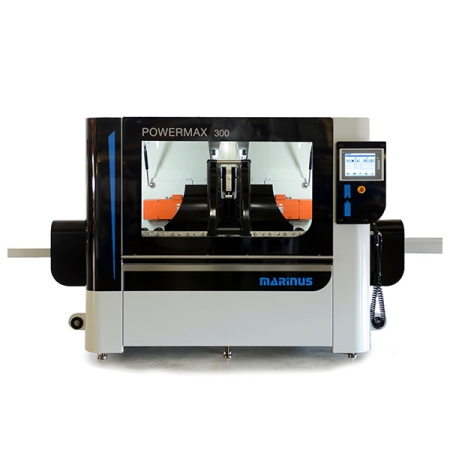

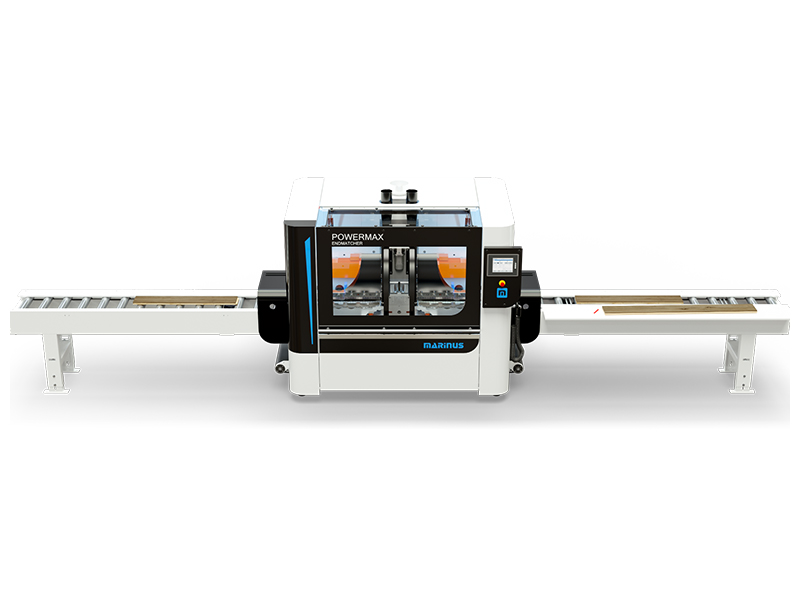

The Marinus Powermax All-in-One Defect Saw and Endmatcher is a high-production End Matcher that can be used for several purposes varying from hardwood/softwood tongue and groove flooring to wall and ceiling paneling. Its unique design combines Defecting, cutting to length, and end matching processes to be carried out in 1 machine, increasing throughput with a reduced footprint. Defecting, cutting to length, and end matching in 1 machine.

Why Marinus Powermax All-in-One Defect Saw and End Matcher?

Unmatched production capacity:

One of the unique features of the Powermax Endmatcher is its production speed. The standard model of the Powermax Endmatcher can produce up to 24 boards per minute! The Powermax Endmatcher is the fastest Defecting and End Matching machine in the market using the flexible ‘Through-feed’ method.

What makes the Powermax so fast?

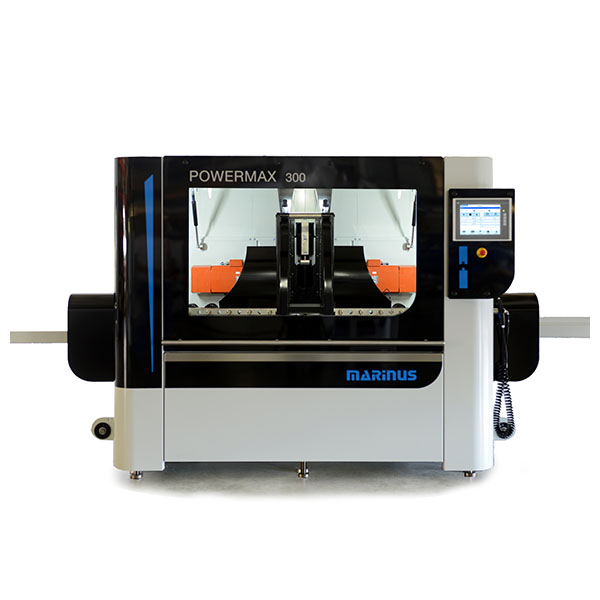

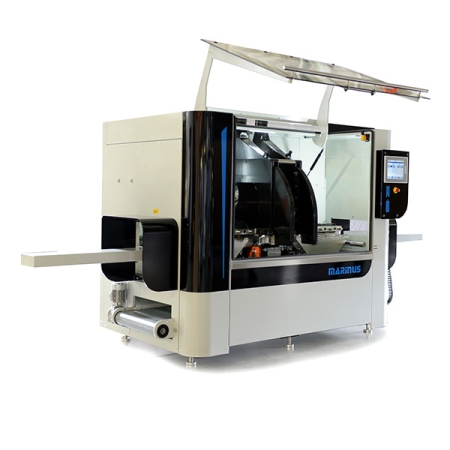

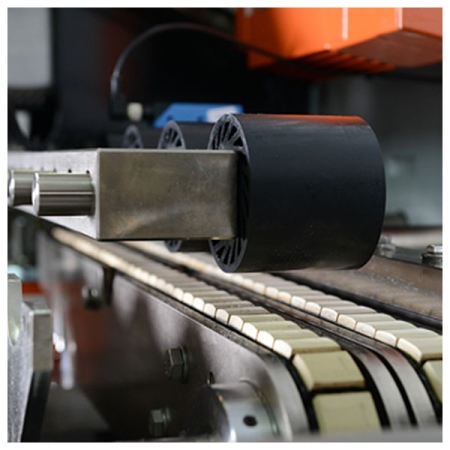

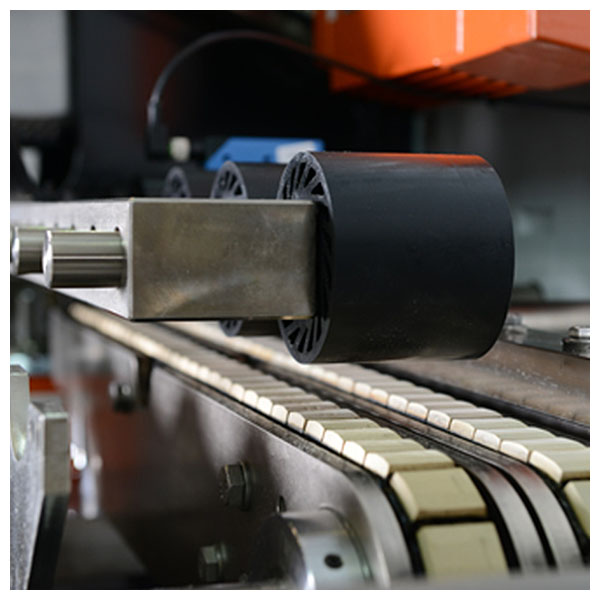

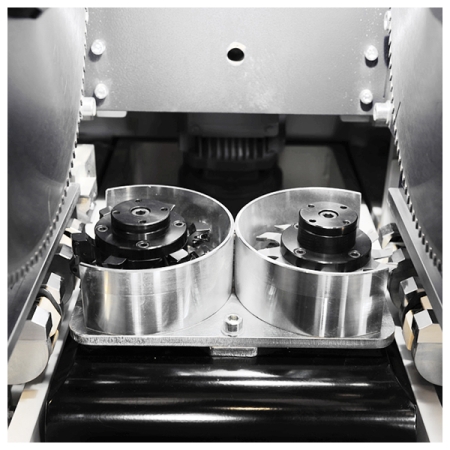

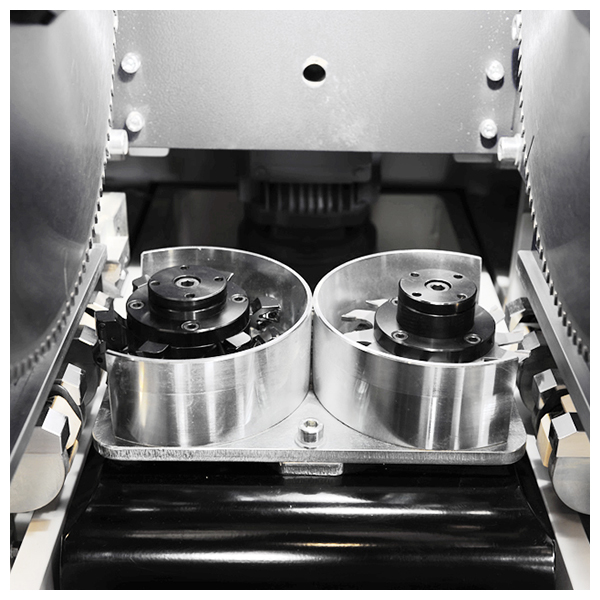

The 12,000 rpm high-speed milling motors combined with our special custom-built tools and servo-steered feeding offer optimized milling conditions for almost every thinkable situation.

Both saw cuts, by infeed and outfeed, are equipped with and supported by a reliable and accurate servo technique. This allows making very fast cuts when high capacity is required. Speed can be easily adjusted for the best result for higher quality jobs and/or critical wood species.

What makes the Powermax so unique?

Defecting & End Matching in one Compact Through-Feed machine line.

The Powermax Endmatcher is unique because of its compactness and combination of production methods. This Through-Feed machine combines Crayon-mark plank defect trimming with precise milling end matching methods. This combination allows you to produce quickly and efficiently with 1 machine.

- Defecting and end matching all one machine increases productivity with reduced footprint

- High capacity throughfeed design with up to 24 boards/min

- 12000 RPM servo controlled milling cutterheads for superior production and finish results

- Servo controlled cut off saws for superior cutting speeds

- User friendly touch screen interface

- High profile accuracy by use of precision linear guides

- Absolute squareness due to firm side pressure clamps

- No Splintering/Blowouts!

- Unique insert carbide profile tooling for high quality Tongue & Groove production

- Advanced servo drive & control technique by Lenze

- Defect crayon mark identification

- Belt conveyor with drive motor for waste

- CE safety and electrical to UL/CSA standards

Nothing Found

Sorry, no posts matched your criteria