High efficiency and high-speed double surface planing.

The Cantek GT610HI Cardan Shaft Drive Double Surface Planer is capable of speeds up to 98 feet per minute and its robust cast-iron body & industrial cardan drive system ensure high production planing day in and day out. The large diameter cutterheads are spiral type with two-sided solid carbide inserts which produce a clean finish with superior stock removal capacity. The spring loaded feed system passes the material over the bottom head allowing it to act like a jointer to flatten the board prior and then a sectional infeed roller feeds the material through the top head for accurate dimensioning.

Why Cantek GT610HI Cardan Shaft Drive Double Surface Planer?

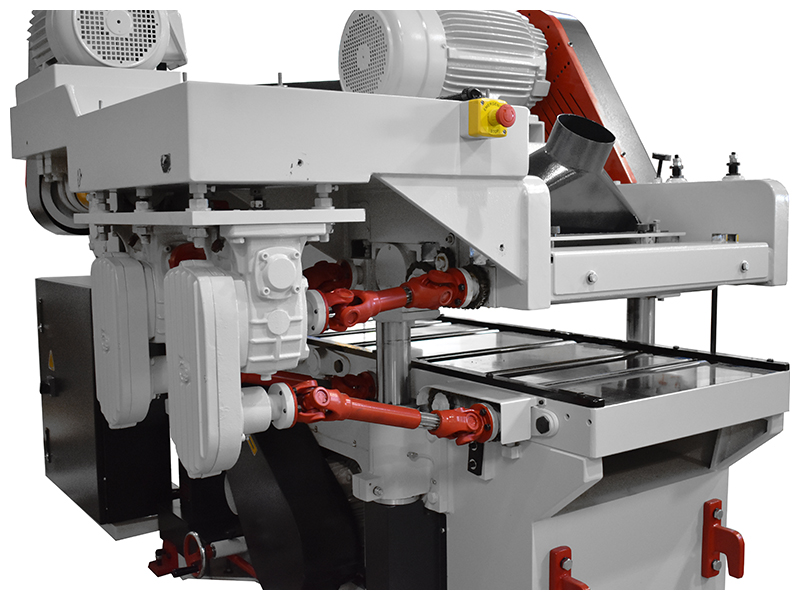

- Powerful 40HP top head motor and 30HP bottom head motor for maximum stock removal

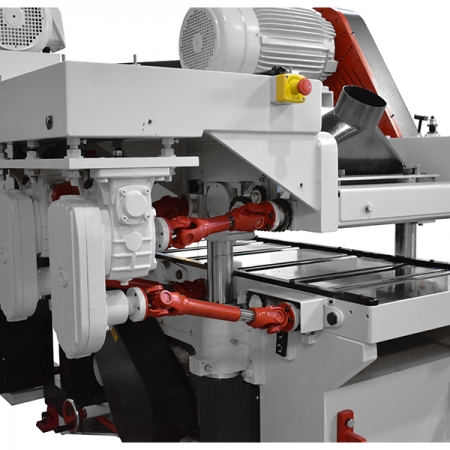

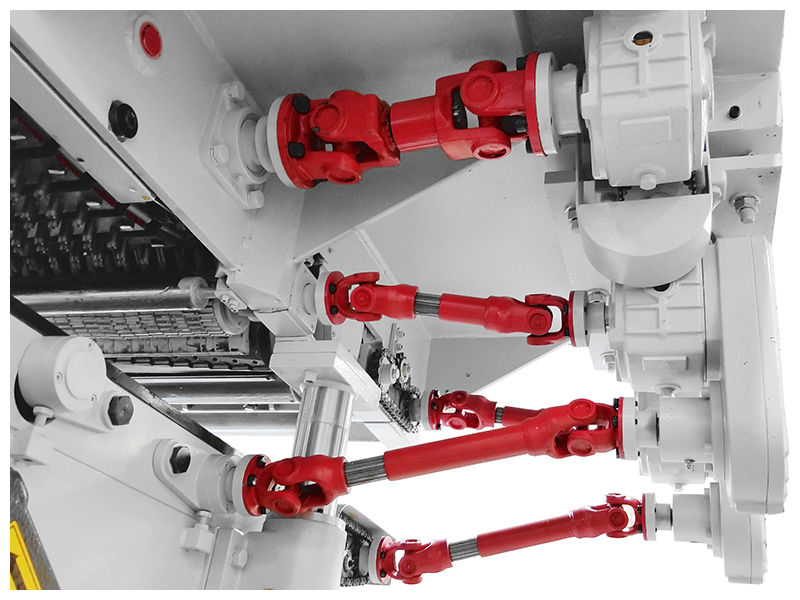

- Full cardan shaft feed system allowing for faster feed speeds up to 98 FPM

- Planing capacity up to 24” wide and 8” thick

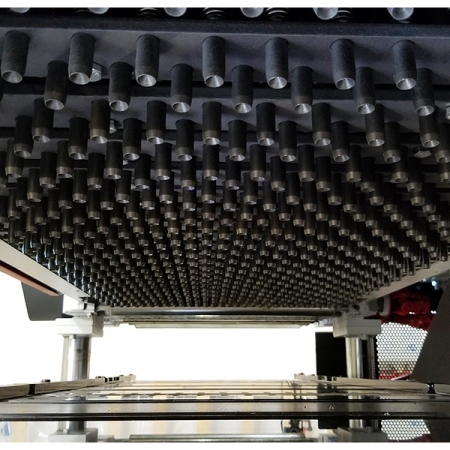

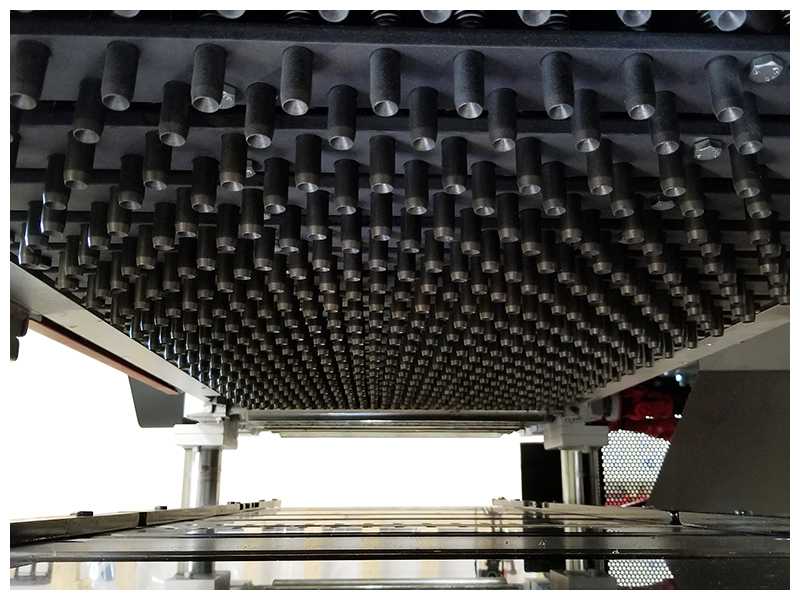

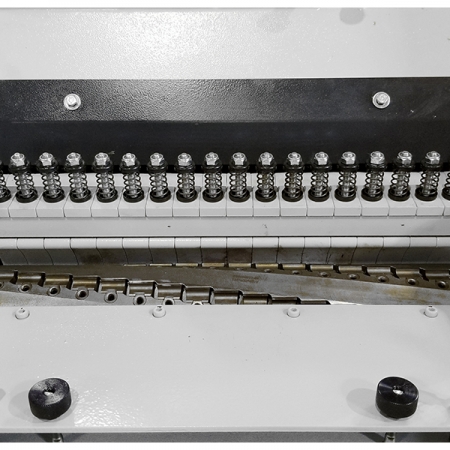

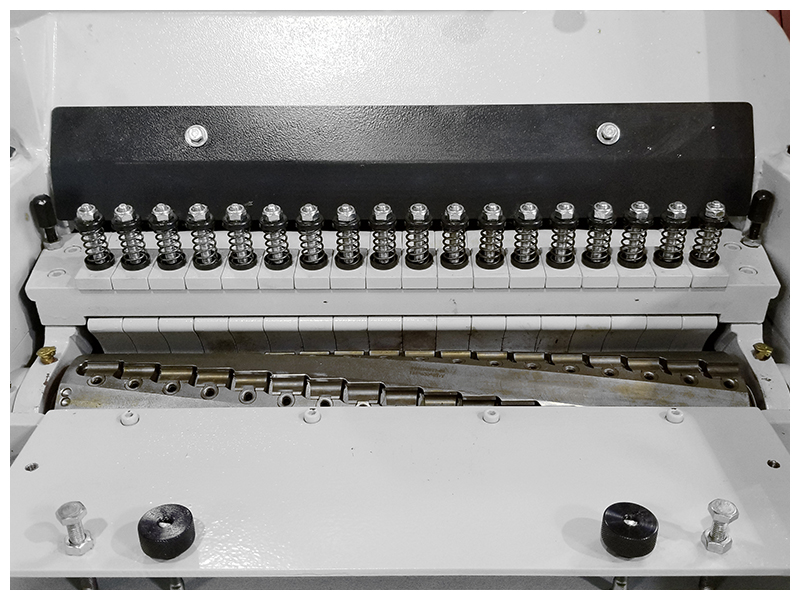

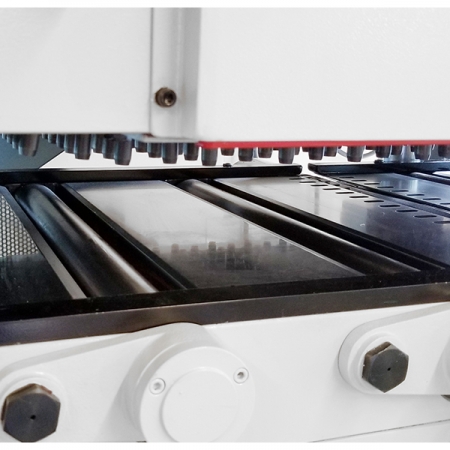

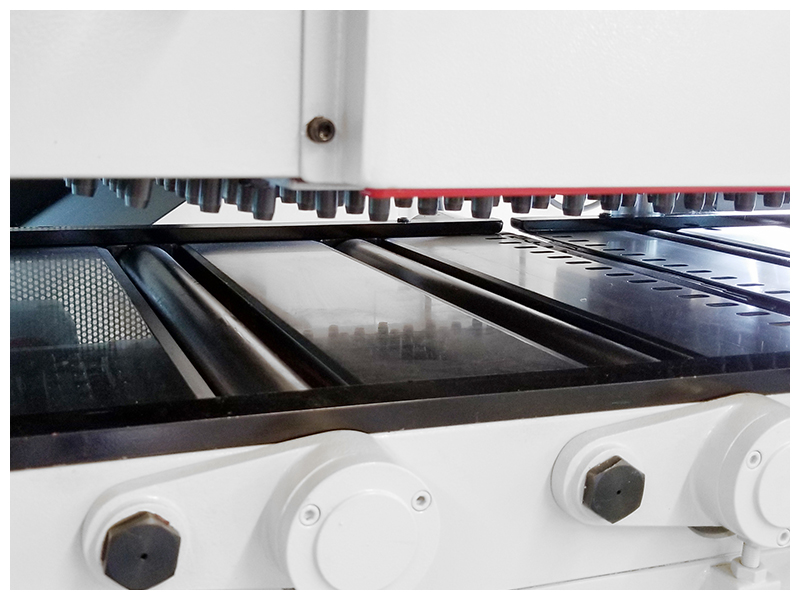

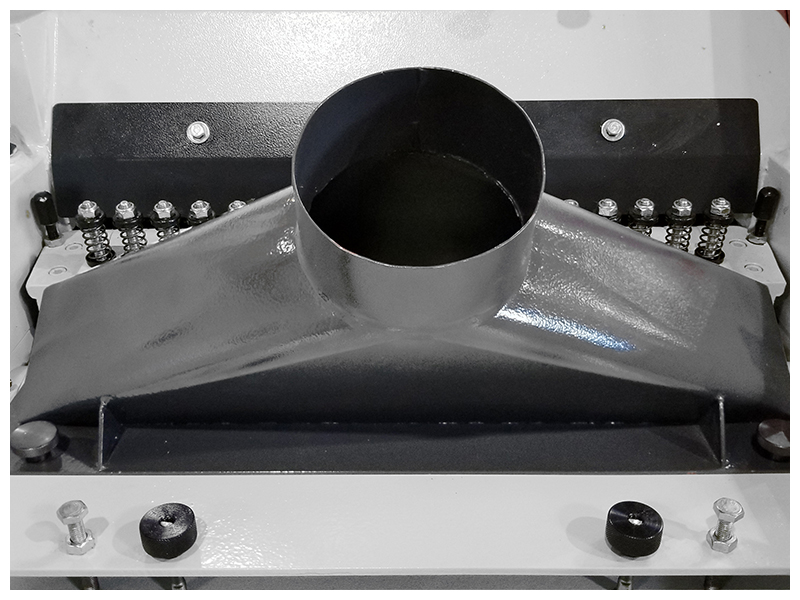

- Pin type carpet feed system passes the material over the bottom head to ensure a flat surface

- (7) bed rollers including (3) driven rolls for superior feed speeds

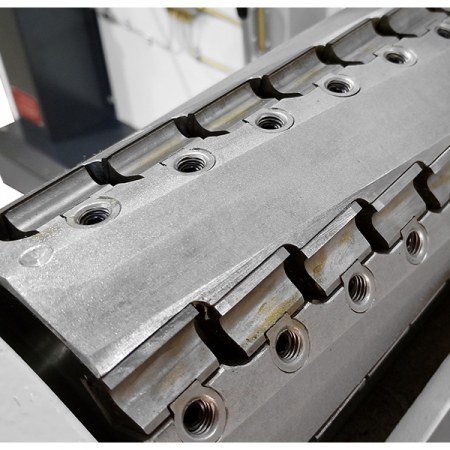

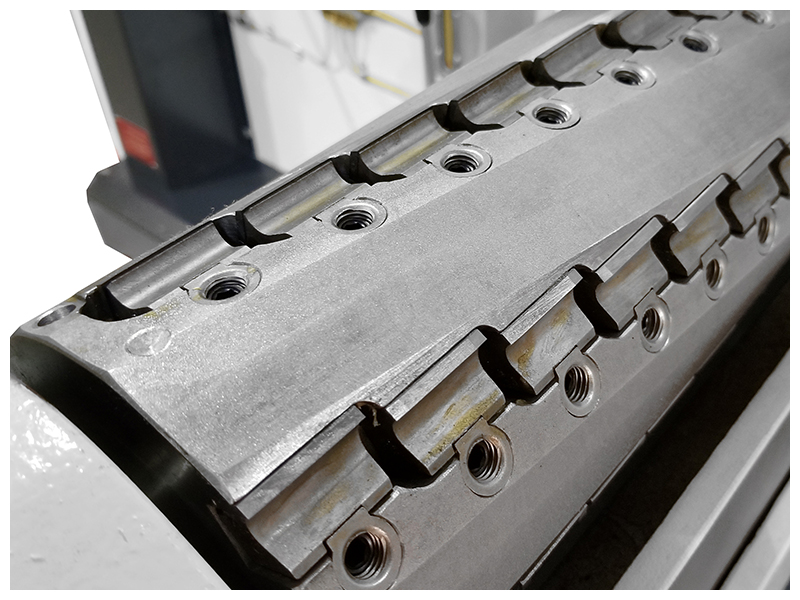

- Spiral insert knife cutterheads with 6 rows of two-sided 30x12x2.5mm solid carbide insert knives provide superior stock removal, reduced machine load and noise, and optimum finish quality

- Cast iron machine frame for superior vibration damping resulting in a long machine & bearing life

- Chrome-plated tables and top and bottom for maximum wear resistance

- Cutterheads are mounted in precision ABEC 7 RHP bearings

- Feed system uses a spring-loaded pin arrangement to pass material over the bottom jointing head.

- Sectional serrated infeed roll before the top cutterhead

- Variable feed speed by frequency inverter (VFD) with digital display for the feed speed

- Digital thickness control for quickly and precisely setting the desired thickness

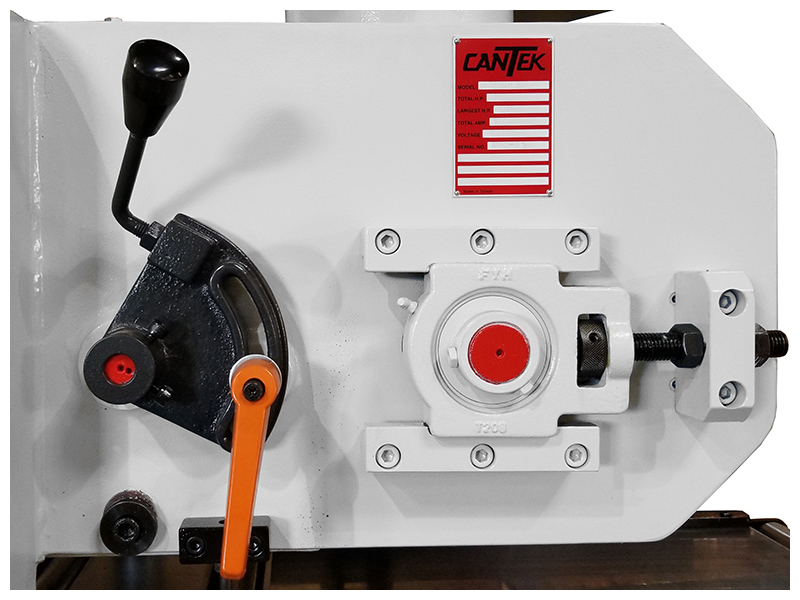

- Upper assembly is adjusted for desired thickness by four large diameter cylindrical posts

- Adjustable infeed bed by easily accessible handwheel to set desired stock removal on the bottom head

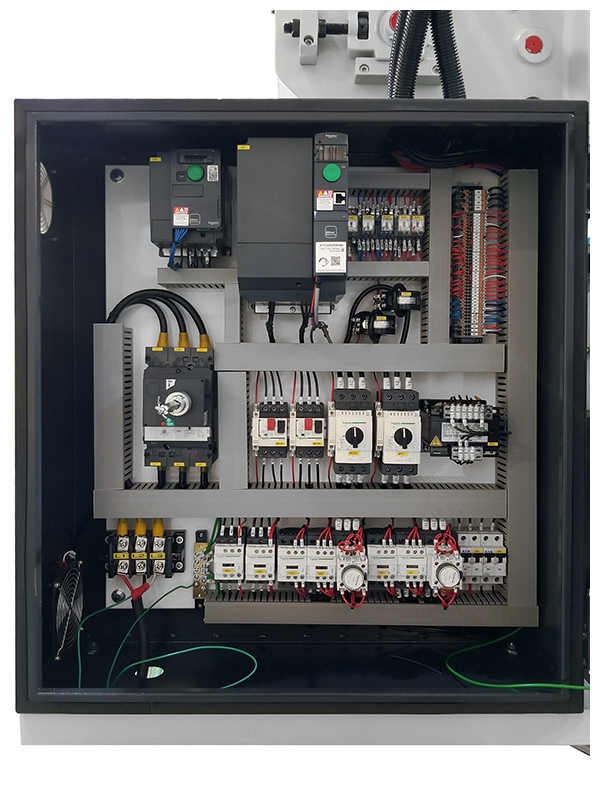

- Easy to access swivel control panel with individual ammeters for load monitoring and hour meter to aid in maintenance planning

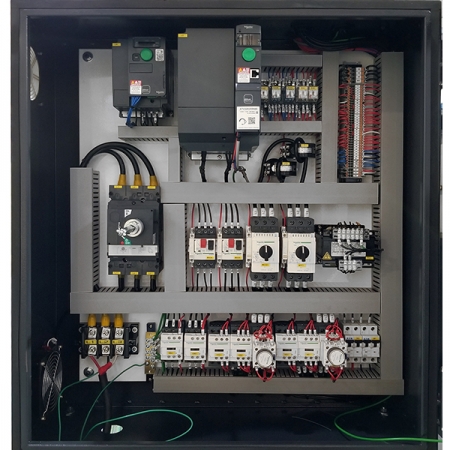

- Cutterhead starters are Y-Delta providing soft start to the heads for reduced power consumption on startup

- Automatic lubrication to the conveyor feed system

- High quality Schneider electrical components to CSA/UL standard